A seamless pipe is a type of cylindrical tube made from a solid block of material. Unlike welded pipes, seamless pipes do not have any seams or joints along their length. This characteristic gives them superior strength and durability, making them ideal for high-pressure applications and harsh environments.

How Are Seamless Pipes Made?

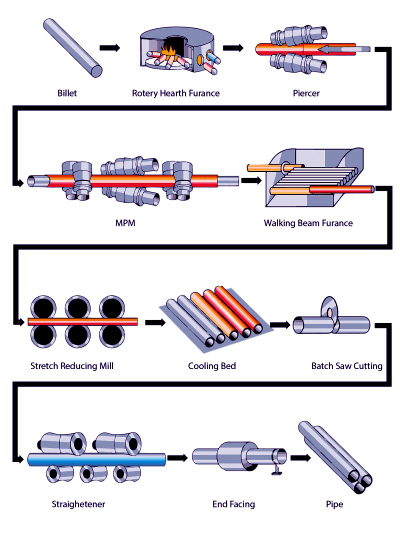

The manufacturing process of seamless pipes is fascinating and involves several critical steps:

- Billet Preparation: The process starts with heating a solid cylindrical block of steel, known as a billet, to a high temperature, making it malleable and ready for shaping.

- Piercing: Next, a powerful rotary piercing machine pierces the heated billet through the center, transforming the solid billet into a hollow tube.

- Elongation: Rolling mills then elongate the hollow tube to the desired length and diameter. During this process, the pipe is repeatedly rolled and stretched until it reaches the required dimensions.

- Sizing: After elongation, the pipe undergoes a sizing process to ensure it meets specific size and shape requirements. This step guarantees uniformity in the pipe’s diameter and wall thickness.

- Heat Treatment: To enhance the mechanical properties of the pipe, it undergoes heat treatment. This process involves heating and cooling the pipe in a controlled manner to improve its strength and durability.

- Finishing: Finally, the seamless pipe is cut to the desired length, inspected for quality, and given any necessary surface treatments. The finished pipe is now ready for various industrial applications.

Material Used in Seamless Pipes

Seamless pipes can be made from an array of various materials, each offering specific properties that cater to particular applications:

Carbon Steel

It is known for its high strength and excellent durability, and is commonly used in making seamless pipes designed for high-pressure applications, such as those applied within oil and gas drilling and power generation.

Stainless Steel

It exhibits excellent corrosion resistance and thus is used for making seamless pipes in those industries where the medium conveys moisture and chemicals, notably chemical processing and food and beverage.

Alloy Steel

Slightly more in their composition are Chromium, Nickel, and Molybdenum, due to which the alloy steel seamless pipes become strong and resistant to heat and corrosion, and thus find applications in high-temperature and high-pressure assignments.

Mild Steel

Seamless pipes made from mild steel can boast good mechanical properties and pocket-friendly prices. Due to that, they can be used in general engineering, construction, and the automotive industry, where high strength and toughness are not demanded by the condition.

Copper

Seamless pipes made from copper are of excellent thermal conductivity and high resistance against corrosion and are commonly used in heat exchangers, plumbing systems, and HVAC systems.

Nickel Alloys

Nickel alloys have superior resistance to corrosion and high temperatures, so these are applied in chemical processing plants and power generation.

Advantages of Seamless Pipes

There are several qualities that a seamless pipe exhibits but are superior to the welded ones, and some of them include:

High Strength and Durability

A seamless pipe, in this case, will be much stronger and will serve in. This makes seamless pipes to have better corrosion resistance than welded ones; they are suited for the oil and gas industries, which subject the material to hostile chemical and environmental conditions.

Versatility

Seamless steel pipes are versatile and can be used for several functions. Their inherent qualities, making them strong, durable, and uniform, make them a material of choice for very critical functions.

Common Applications of Seamless Pipes

Due to their excellent qualities, seamless pipes find application in numerous industries. Listed below are some of the common applications of seamless pipes:

Oil and Gas Industry

Seamless pipes are vastly used in the oil and gas sector in drilling, transportation, and processing. This makes them ideal in this application since they can easily stand a very high pressure and an aggressive environment.

Automotive Industry

The seamless pipes are found in the automobile industry from very minute applications to some of the most critical, for instance, in the making of fuel injection systems and drive shafts. This application is because of the qualities of precision and strength in seamless pipes, which surmount to immense significance in the performance and safety of vehicles.

Power Generation

Seamless pipes are used in power plants in applications like boilers and heat exchangers. This is due to the high pressure; therefore, they have to be strong and have the ability to withstand very hot temperatures.

Construction

Seamless pipes find application for structural purposes in construction, such as building frameworks, scaffolding, and pipelines. The fundamental nature equips them with strength and uniformity, thus guaranteeing the structures’ stability and safety.

Conclusion

Seamless pipes are a very vital element in very many industries, recognized due to their great strength, uniformity, and better corrosion resistance. Knowing how they are manufactured and what their advantages are can greatly help in determining what their functions will be in any specific application. As technology develops, seamless pipes shall have a critical role in the construction and maintenance of key infrastructure and industrial systems.