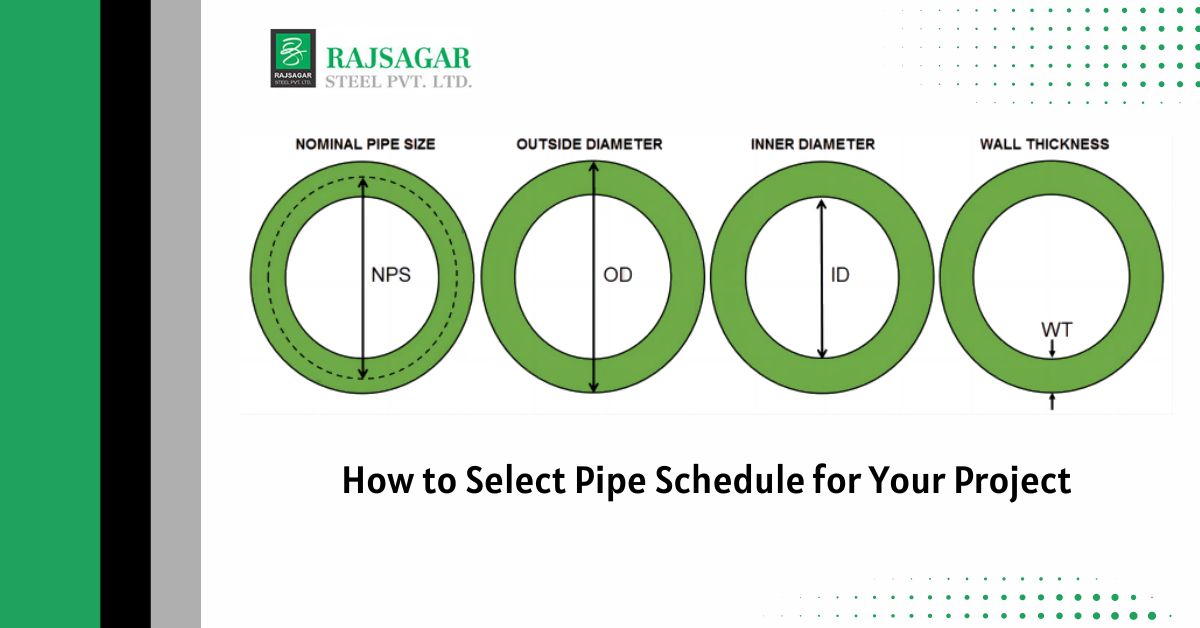

The selection of an appropriate pipe schedule is an essential component of any successful plumbing project planning. The pipe schedule, indicated by a schedule number, describes the pipe wall’s thickness. This value determines the pressure capacity and pipe strength. You can choose the right pipe schedule for your project with the help of these simple instructions.

Understanding Pipe Schedule

Pipe schedule is one of the most popular methods for determining the thickness of the pipe walls about the pipe’s nominal size. It assists in choosing the right pipe for the particular pressure and temperature range needed for the pipe. A low schedule number means that the walls of the building are thin and if the schedule number of a certain column is high, then it means that the building has thicker walls. For instance, Schedule 40 pipes also have a larger diameter than Schedule 20 pipes but the thickness of walls of both the pipes differ.

Factors to Consider

Operating Conditions: Consider the pressure and temperature conditions the pipe will encounter during operation. Higher pressures and temperatures typically necessitate pipes with thicker walls to withstand the stress.

Nature of Fluid: The type of fluid being transported through the pipe is critical. Corrosive substances, high-temperature fluids, or abrasive materials may require pipes with thicker walls to prevent damage and ensure safety.

Application Requirements: Different applications demand varying levels of pipe strength and durability. For instance, industrial processes might require heavy-duty pipes with thicker walls, while residential plumbing systems may suffice with lighter schedules.

Budget Constraints: Thicker-walled pipes are generally more expensive due to the additional material and manufacturing processes involved. Balancing performance requirements with budget constraints is essential.

Selecting the Right Pipe Schedule

- Identify Project Requirements: Determine the operating conditions, including pressure, temperature, and fluid properties.

- Consider Safety Factors: Factor in a safety margin when selecting the pipe schedule to ensure the system can handle unexpected pressure fluctuations or operational stresses.

- Quality Assurance: Ensure that pipes meet relevant industry standards and undergo proper quality testing to guarantee performance and safety.

- Calculate Pressure Ratings: Use pressure rating charts or formulas provided by pipe manufacturers to calculate the required schedule for your project’s operating pressure.

Summary

Choosing the appropriate pipe schedule can make a significant difference in the functionality, safety, and durability of your pipe work. Therefore, if you are considering working operating conditions, the type of fluid, the applications that you need for the project, and the cost, you can be able to arrive at a decision that will suit your project. Regardless of whether the specific application requires Schedule 10 for residential plumbing or Schedule 80 for industrial usage, deciding on the right pipe schedule is the first step towards creating a strong and long-lasting system. Please keep in mind that you’ll not regret the initial time and effort you spent choosing the appropriate pipe schedule.